Frequently Asked Questions ABchimie

Your questions answered about PCBA protection.

Find clear, expert answers to the most common questions about protecting

printed circuit boards (PCBs) and choosing the right solutions for your application.

Where can I get Safety Data Sheets (SDS) and Technical Data Sheets (TDS) for ABchimie products?

Access to Technical and Safety Data Sheets

All of our technical data sheets are available in both French and English on our website: www.abchimie.com. They are regularly updated to reflect the latest product information.

For safety data sheets (SDS), please feel free to request them by email at contact@abchimie.com. Our team will respond promptly.

What are the essential properties of conformal coatings?

Conformal coatings are applied to printed circuit boards (PCBs) to protect them from harsh environmental conditions and to enhance their long-term reliability and operational lifespan.

These coatings offer a combination of critical properties, including:

-

Electrical Properties: Provide insulation to prevent short circuits and electrical failures.

-

Physical Properties: Ensure strong adhesion to the substrate and maintain surface hardness.

-

Mechanical Properties: Offer resistance to abrasion and vibration, and help reduce the formation of tin whiskers.

-

Chemical Properties: Protect against exposure to aggressive chemicals—such as solvents, acids, and alkalis—in both liquid and vapor forms.

What do conformal coatings or resins protect against?

Conformal coatings generally protect PCBs from environmental factors such as humidity, airborne gases, dust, and fine particles. Resins, on the other hand, offer robust mechanical protection and electrical insulation—even in harsh conditions, including immersion in water or exposure to aggressive chemicals.

Depending on the operating environment, either technology may be best suited to protect your PCB from:

- Corrosion

- Short circuits

- Basic tampering or low-level hacking

- Mechanical shocks

The goal is to:

- Enhance reliability

- Prolong the lifespan of the assembly

- Improve the PCB’s electrical insulation

How to select a conformal coating?

Choosing the Right Conformal Coating

Selecting the appropriate conformal coating for your application is a critical decision that depends on multiple factors. The right choice must align with the environmental conditions of the PCB, your production capabilities, the volume of boards to be manufactured, and overall material costs.

To help guide your selection, consider the following key questions:

-

What is the operating temperature range?

-

What environmental conditions will the PCB face (e.g., humidity, chemical exposure, abrasion)?

-

Is easy rework or repairability important?

-

Are there specific qualifications or standards required (UL, MIL, IPC, etc.)?

-

Which application method will be used (brush, spray, dip, or selective machine)?

-

What types of tests will be performed?

-

What is the allowed process time?

-

What is your target cost?

In many cases, the answers to these questions can quickly narrow down the most suitable type of conformal coating. However, trade-offs may be necessary—for example, a coating that is highly resistant to solvents is typically more difficult to repair.

Therefore, it’s important to clearly define and prioritize your performance and process requirements.

These questions are also essential for ABchimie teams to recommend the best conformal coating for your specific application. If you need assistance in making the right choice, feel free to contact us at: contact@abchimie.com

How to apply a conformal coating?

Conformal Coating Application Methods

There are four primary methods for applying conformal coatings:

-

Brush Application

This is the most basic and cost-effective method, requiring only a brush. It’s especially suitable for small-scale maintenance and repair work. However, results can vary depending on the operator’s skill, and issues such as uneven coating, bubbles, excessive thickness, and contamination from the brush may occur. Additionally, operators must be protected from solvent exposure during application. -

Spray Application (Aerosol or Spray Gun)

Spraying with either an aerosol can or a spray gun is a relatively low-cost method that provides good coating uniformity. To ensure proper coverage and consistent film thickness, it is recommended to apply four coats using a cross-pattern at 90° angles (known as cross passes). A significant drawback of this method is the time required for masking and unmasking components that must be protected from coating. -

Dipping (Soaking)

Dipping is a fast method that can provide an even coating if performed correctly. The recommended process includes an immersion rate of 20 cm per minute and a withdrawal rate of 10 cm per minute, leveraging the lift-out effect for optimal results. However, this method requires the PCB to be specifically designed for dipping, including appropriate clearances and layout considerations. -

Automated Selective Coating

This is the most advanced and widely used method in modern manufacturing. While it involves a higher initial investment, it offers several significant advantages:

-

High throughput

-

Excellent repeatability

-

Precisely controlled coating thickness

-

No need for manual masking/unmasking

-

Each method has its own use cases depending on the production scale, design constraints, and quality requirements.

Solved based vs Solvent free: What to choose?

Solvent-Based Conformal Coatings: Still the Industry Standard—For Now

Today, solvent-based systems still dominate approximately 80% of the conformal coating market. This is due to a combination of historical, technical, and economic factors, including:

-

Improved Viscosity: Solvents lower the viscosity of coatings, making them easier to apply.

-

Surface Preparation: They help clean the substrate, promoting better wetting and adhesion.

-

Fast Processing: Solvent evaporation allows for rapid drying and produces thin, cost-effective coatings.

While solvents offer clear advantages in application performance, they pose significant environmental and health risks. The Solvent Emissions Directive from the European Community (EC) plays a key role in reducing industrial emissions of volatile organic compounds (VOCs), and is driving the industry toward greener alternatives.

At ABchimie, we’re committed to developing environmentally responsible, solvent-free technologies to protect your PCBAs—without compromising on performance.

Shifting to Solvent-Free: A Gradual Transition

Switching from solvent-based to solvent-free coatings is not always straightforward. Existing production lines often require major equipment changes, making immediate transitions rare. However, interest in solvent-free solutions is growing rapidly. As a result, these options are now frequently included in new product qualifications and future project planning.

The market is evolving—and the shift is only a matter of time.

How to Prepare a PCB for Conformal Coating?

Proper preparation is essential to ensure the performance and durability of conformal coatings. Both PCB design and pre-coating conditions play a critical role.

Design Considerations

To achieve optimal results, the PCB should be designed with coating in mind. Follow these key guidelines:

-

Define Coating Zones: Clearly identify coated, tolerable, and prohibited areas.

-

Component Placement: Avoid placing components that require coating next to those that must remain uncoated. Maintain a minimum spacing of 4 mm between them.

-

Via Design: Use filled vias wherever possible. If unfilled vias are necessary, ensure they do not connect to prohibited areas.

-

Dipping Applications: For dip coating, position all non-sealed connectors and sensitive components along the same outer edge of the PCB to prevent unwanted coating intrusion.

Pre-Coating Preparation

Before applying any conformal coating, ensure the following conditions are met:

-

Dryness: The PCB must be completely dry. Keep in mind that FR4 material can fully reabsorb ambient moisture within 72 hours. Moisture in the substrate can hinder coating adhesion and compromise protection. If the board is not coated immediately after the SMT process, bake it in an oven to eliminate residual moisture.

-

Cleanliness: The PCB surface must be free from contamination. Any residues—such as flux, oils, or dust—can reduce coating adhesion. If cleaning is not performed, it’s recommended to verify adhesion using a cross-hatch test according to ISO 2409. Additionally, surface energy testing can be used to assess the PCB’s suitability for coating.

Is PCB cleaning required before applying a conformal coating?

Although 95% of coating users skip PCB cleaning due to associated costs, this step remains crucial for military, aerospace, and medical applications.

Cleaning adds an extra process stage but plays a vital role in enhancing coating performance. It uniformly increases the surface tension of the PCB, improving the wettability of the conformal coating. By removing contaminants such as silicone residues, oils, and adhesive traces, cleaning prevents dewetting issues and ensures stronger adhesion. This process also helps avoid chemical compatibility problems between the coating, flux, solder residues, and the substrate.

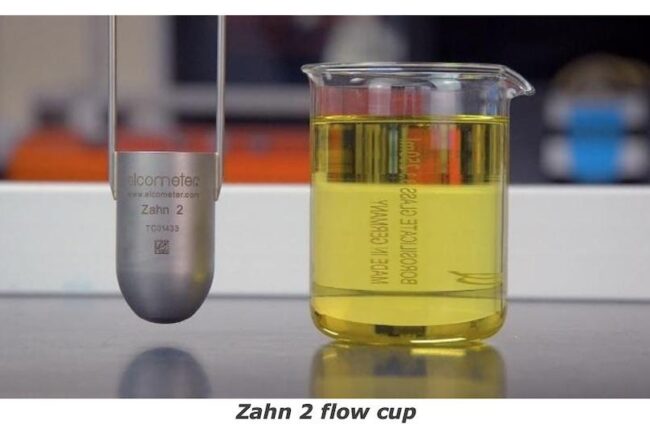

How to Check the Viscosity of a Conformal Coating Material?

The quickest and simplest way to measure the viscosity of a conformal coating is by using a flow cup. This tool, typically made of stainless steel with a small hole drilled at the center of its bottom, measures the kinematic viscosity by recording the flow time of the liquid, expressed in seconds.

There are various types of flow cups available on the market. For example, for our popular solvent-based acrylic coating, ABchimie AVR80 BA DS 65, we recommend using a Zahn 2 cup.

Measurement Procedure:

-

Fully immerse the flow cup in the conformal coating material to fill it completely.

-

Lift the cup out of the liquid and immediately start a stopwatch.

-

Measure the time it takes for the liquid to flow out through the hole.

-

Stop the stopwatch as soon as the liquid stream breaks.

The recorded flow time (in seconds) can then be converted to kinematic viscosity (in centistokes, cSt) using a viscosity conversion chart.

Additional Notes:

-

Centistokes (cSt) measure kinematic viscosity and are determined (using flow cups).

-

Centipoise (cPs) measure dynamic viscosity and are typically obtained with instruments like a Brookfield viscometer. (using a Brookfield for example) cSt = cPs/density.

-

Always record the temperature of the material during the test, as viscosity decreases with increasing temperature.

ABchimie offers several ‘ready-to-use’ conformal coating formulations tailored to different application needs and processes.

What thickness of conformal coating should be applied?

Generally, a thickness of 25 to 50 microns is sufficient to protect your pcb. The IPC CC 830 standard recommends 30 to 130 microns depending on the chemical nature of the conformal coating used. Please note that too thick may create delamination and cracking problems.

What flash off time should be applied to a coating line?

Determining the ideal flash-off time is a complex matter—it’s not just about the volume of air extracted. Flash-off time refers to the period after applying the coating during which most solvents evaporate before the PCB enters the inline IR oven.

It is crucial to avoid excessive airflow directly over the freshly coated PCB surface. Too strong an airflow can cause a “skin” to form on the coating’s surface, trapping solvents underneath. This skin effect significantly prolongs drying time and increases the risk of bubbles and cracks forming in the coating.

To minimise drying time and prevent skin formation, the air extraction system should ensure consistent air renewal rather than high-velocity airflow over the board. If the current extractor cannot be adjusted, installing a variable speed drive or increasing the size of the air intake openings can help. Enlarging the openings lowers the air velocity at the PCB surface, reducing the risk of skin formation.

Typically, PCBs are allowed a minimum of 2 minutes in the flash-off zone before proceeding to the next stage, such as curing in an inline IR oven.

How to promote the evaporation of solvents?

Solvent Extraction During Conformal Coating Application

When applying solvent-based conformal coatings, proper solvent extraction is essential for two key reasons:

-

Operator Safety – To minimize exposure to potentially hazardous solvent fumes.

-

Coating Quality – To ensure that only the dry resin remains on the PCB surface after application.

The type of extraction system required depends on the application method—whether using aerosol, spray gun, manual brush, or automated dispensing equipment. For spray applications, high-performance spray booths are commonly used and widely available on the market.

For automated dispensing systems, the setup typically includes a flash-off zone—an extraction area designed to manage solvent evaporation before curing. This zone must be correctly sized based on several factors:

-

The number of PCBs being processed

-

The specific solvent used

-

The production line speed

It’s important to note that extraction should be limited to gentle air renewal. Excessive airflow can lead to issues like surface skinning, which traps solvents and affects drying (refer to: What flash-off time is required for my conformal coating line?).

How can the ``orange peel`` effect be removed from a PCB?

Understanding and Eliminating the “Orange Peel” Effect in Solvent-Based Conformal Coatings

The “orange peel” effect typically occurs with solvent-based conformal coatings when the coating mixture begins to shrink before leveling, preventing a smooth, uniform surface. This issue is usually caused by solvents evaporating too quickly, which disrupts the formation of a consistent film.

To address the problem, it’s important to identify the stage in the process where the issue originates.

A practical approach is to inspect the coated PCB at the exit of each key zone in your conformal coating line:

-

Coating application system

-

Flash-off zone

-

Curing oven

Once the stage causing the orange peel is identified, the solution generally involves reducing the airflow or extraction power within that section. Slowing down solvent evaporation allows the coating to level properly, eliminating the textured appearance.

What causes bubbles to form on PCBs?

Bubbles on a PCB after conformal coating can result from several factors, including:

-

Overlapping passes during dispensing, which can trap air between layers.

-

Excessive air extraction, leading to a skin effect that traps solvent or air beneath the surface.

-

Pressurized air supply, especially in the case of acrylic coatings (Henry’s Law effect).

-

Air intake due to an unsealed or leaking application system.

-

Air entrapment caused by spray impact on sharp component edges.

-

Manual brush application, which can introduce air into the coating.

-

Single-step encapsulation, such as over a BGA, which may trap air beneath the coating.

How can the cobwebbing effect be eliminated during spray application (particularly with a spray gun)?

The appearance of “cobwebs” or the “cotton candy” effect during spray application—particularly with spray guns—is typically caused by the coating drying too quickly in the air before reaching the PCB surface. This issue is most commonly observed with solvent-based acrylic conformal coatings.

Here’s what happens: during spray application, the coating is atomized into fine droplets. If the solvent in these droplets evaporates too quickly—often due to high air pressure, temperature, or low humidity—the coating begins to dry mid-air. As a result, dry acrylic strands form in the spray path, creating the web-like filaments that deposit unevenly on or around the PCB.

How to avoid cobwebbing effect ?

To prevent cobwebbing caused by premature drying of the conformal coating, several parameters can be adjusted:

-

Add a thinner to reduce viscosity.

-

Use a slower-evaporating thinner to extend drying time.

-

Lower the atomizing pressure to minimize droplet dispersion and slow evaporation.

These adjustments help delay solvent evaporation, ensuring the coating reaches the PCB surface in a liquid state and forms a smooth, uniform film.

At ABchimie, we also offer ready-to-use conformal coatings that are specifically formulated for spray application, minimising the risk of cobwebbing and ensuring consistent results.

What to do with conformal coating waste (cleaners and empty cans)?

Waste Disposal Regulations for Conformal Coating Materials

Waste regulations vary by country. In France, waste from conformal coating materials is classified as hazardous waste or Dangerous Industrial Waste (DID) and must be handled and disposed of by licensed professionals.

We recommend placing a dedicated sorting bin for your DID waste, which should include:

-

Uncleaned, empty, or soiled packaging: This includes containers such as barrels, pots, cans, syringes, aerosols, etc., that have held varnishes, resins, silicones, or similar products. Even when empty, these containers are considered hazardous due to residual product.

-

Soiled materials: Items that have come into contact with conformal coating products, such as personal protective equipment (PPE), rags, contaminated glassware, absorbent materials, and more.

Proper segregation and disposal of these materials are essential to comply with regulations and ensure environmental safety.

Why is it important to apply protective conformal coatings or resins on PCBs?

Whenever an electronic sub-assembly is exposed to harsh conditions—such as humidity, chemicals, or extreme temperature fluctuations—it should be protected with a conformal coating to ensure long-term reliability and extend its service life.

Do you offer non-CMR products?

ABchimie is committed to a strict environmental policy. When developing new products, our laboratory team prioritizes the selection of the least toxic raw materials to create safer, more environmentally friendly formulations.

We also closely monitor regulatory changes to ensure compliance and promptly provide alternative solutions whenever raw materials are affected by evolving legislation.

Do you offer UL94 V0 products?

The UL94 test is the industry standard for assessing the flammability safety of materials. Products that meet the highest flame-retardant rating are often labeled UL94 V0.

Among our conformal coatings, the following are UL94 V0 certified:

-

AVR80 BA, AVR80, AVR80 MP (acrylic coatings)

-

SVR99 (silicone coating)

-

ABchimie 746E UV (urethane-acrylate UV coating)

-

ABchimie 42K UV (urethane-acrylate UV coating)

-

ABchimie 526 UV (urethane-acrylate UV coating)

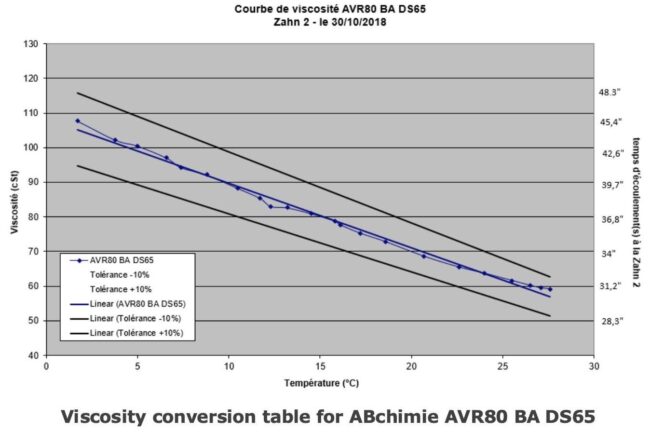

Choosing Between Resins and Conformal Coatings: What You Need to Know

Choosing Between Conformal Coating and Resin (Polyurethane or 2-Component Epoxy Resin)

The choice between a conformal coating and a resin depends largely on the level of protection required, which may or may not make the decision straightforward. To simplify this, it helps to understand the primary purpose of each:

-

Conformal Coating:

This is a thin, insulating layer applied to protect PCBs. In outdoor environments, PCBs are usually housed in enclosures that shield them from direct exposure to rain but still subject them to temperature variations that can cause condensation. In these conditions, conformal coatings primarily prevent corrosion, which can lead to PCB failure. -

Resin:

Resins are designed for much harsher environments. They fully encapsulate PCBs, isolating the electronics completely from the external environment. Resins provide superior mechanical and chemical protection compared to conformal coatings and are often used as a form of housing. They can protect PCBs from rain and even prolonged immersion in water.

Below is a summary table to help guide your choice between a conformal coating and a resin based on your specific application needs.

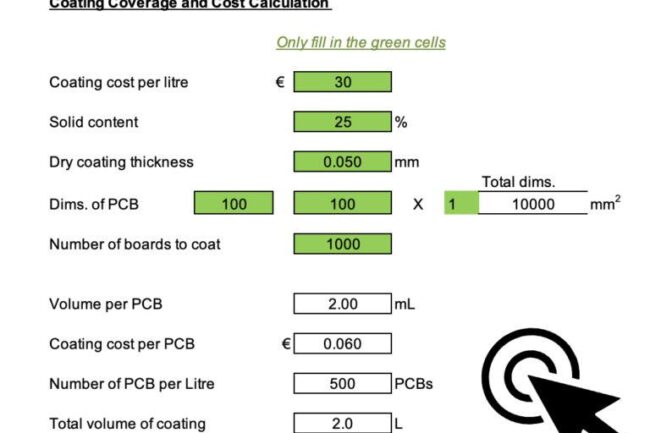

How to calculate a conformal coating coverage and cost?

The true cost of a conformal coating goes beyond the basic price per liter (€/L). More importantly, it depends on the coating coverage—the ability of the material to cover a given surface area at a specified thickness. Therefore, the cost per board (€/PCB) is a far more meaningful metric when evaluating the real expense of a conformal coating or comparing different products.

To simplify this calculation, ABchimie has developed a handy tool that automatically estimates coating coverage, costs, and other related factors based on key inputs such as:

- Coating cost per liter

- Solid content (%)

- Dry coating thickness

- PCB dimensions

- Number of sides to coat

- Quantity of boards to coat

Simply enter your data into the green fields, and the tool will calculate the volume of coating needed per PCB, the cost per PCB, how many PCBs can be coated per liter, and the total volume required for your project.

Coating coverage and cost calculation example

In this example, coating one side of a 100 x 100 mm PCB at a thickness of 50 microns results in a true conformal coating cost of €0.060 per PCB. To put this into perspective, the cost of conformal coating is generally quite minimal, typically representing:

-

Less than 2% of the total PCB cost when considering material costs alone.

-

Less than 8% of the total PCB cost when factoring in both material and processing expenses (including machinery, process time, energy, and floor space).

Click below to Download the coating calculator.

Advanced Cleaning &

Protection Solutions

for Reliable Electronics

- Environmentally friendly solutions to protect your PCBA.