Featured

CONFORMAL COATING

ABchimie’s conformal coating are specially developed to ensure high protection to PCBAs from their environment. They don’t only improve and extend the working life but also can provide reliability and performance. They protect PCBA against harsh environment such as salt spray, humidity, temperature, solvent, dust …with, in general, a thin layer (25 to 50 microns). These environmental conditions can cause damage as corrosion, current leakage and failure.

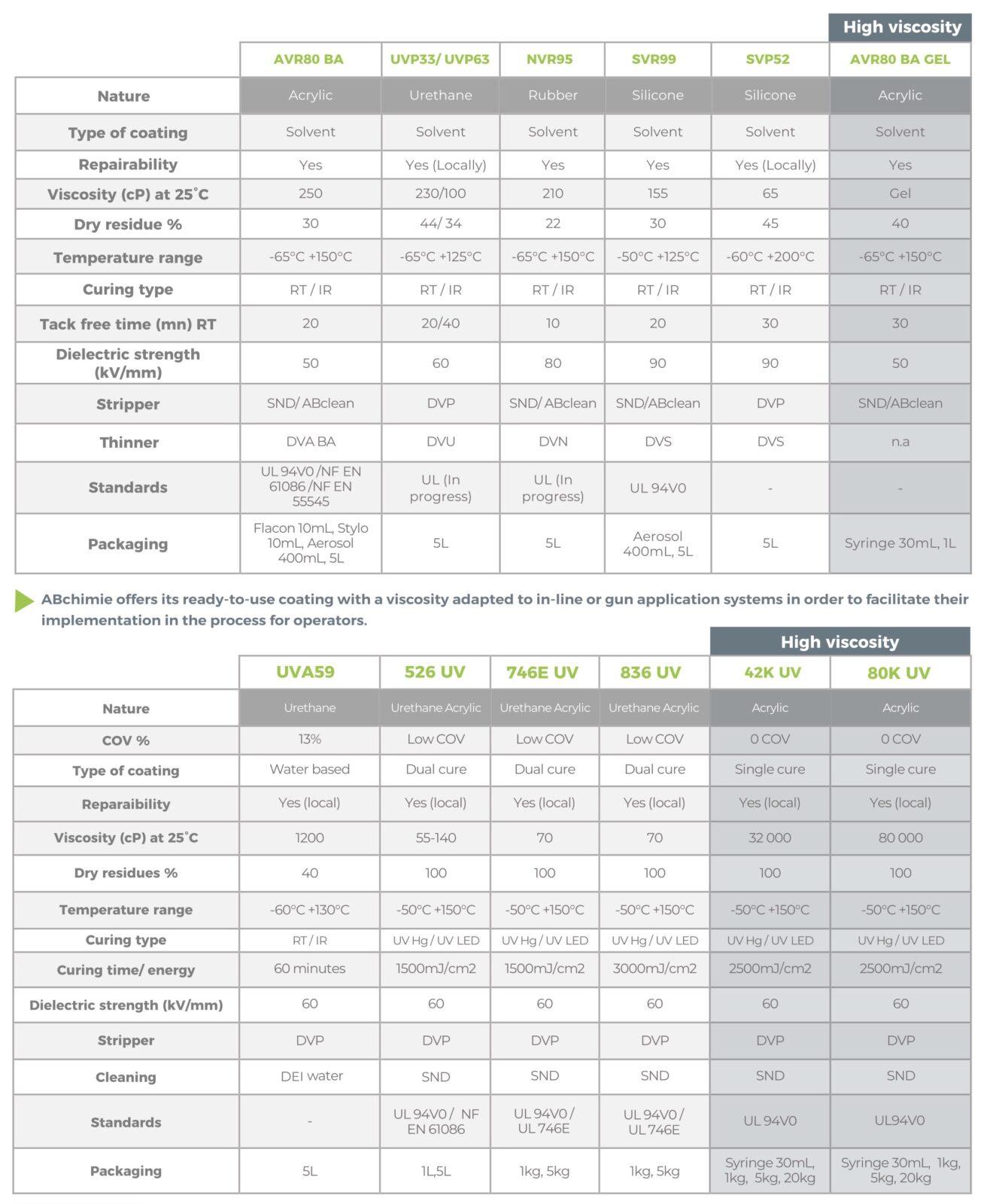

The complete range proposes different base of raw materials: