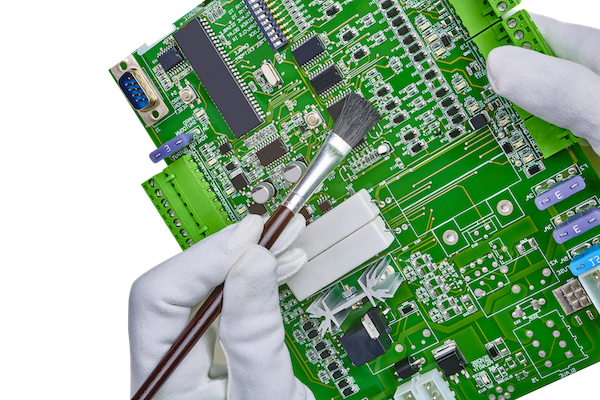

CLEANING PRODUCTS FOR PCBA

ABchimie’s Cleaning Products: Ensuring Reliability and Optimal PCBAs Performance through Cleanliness.

The reliability of printed circuit board assemblies (PCBAs) depends greatly on the cleanliness of the boards. After soldering, flux residues, greases, and other contaminants can remain on the surface. If these are not removed, they can compromise the performance, durability, and reliability of the assembly.

ABchimie has developed a complete range of cleaning solvents and detergents designed specifically for this purpose. These products meet international military cleanliness standards of 1.54 mg NaCl/cm² and are formulated to be compatible with the majority of plastics used in electronic assemblies. By effectively removing contaminants, they not only improve the long-term stability of electronic sub-assemblies but also ensure the proper adhesion of conformal coatings during varnishing operations. For these reasons, cleaning electronic boards after soldering is not simply a recommendation but an essential step when long-term reliability and high performance are required.

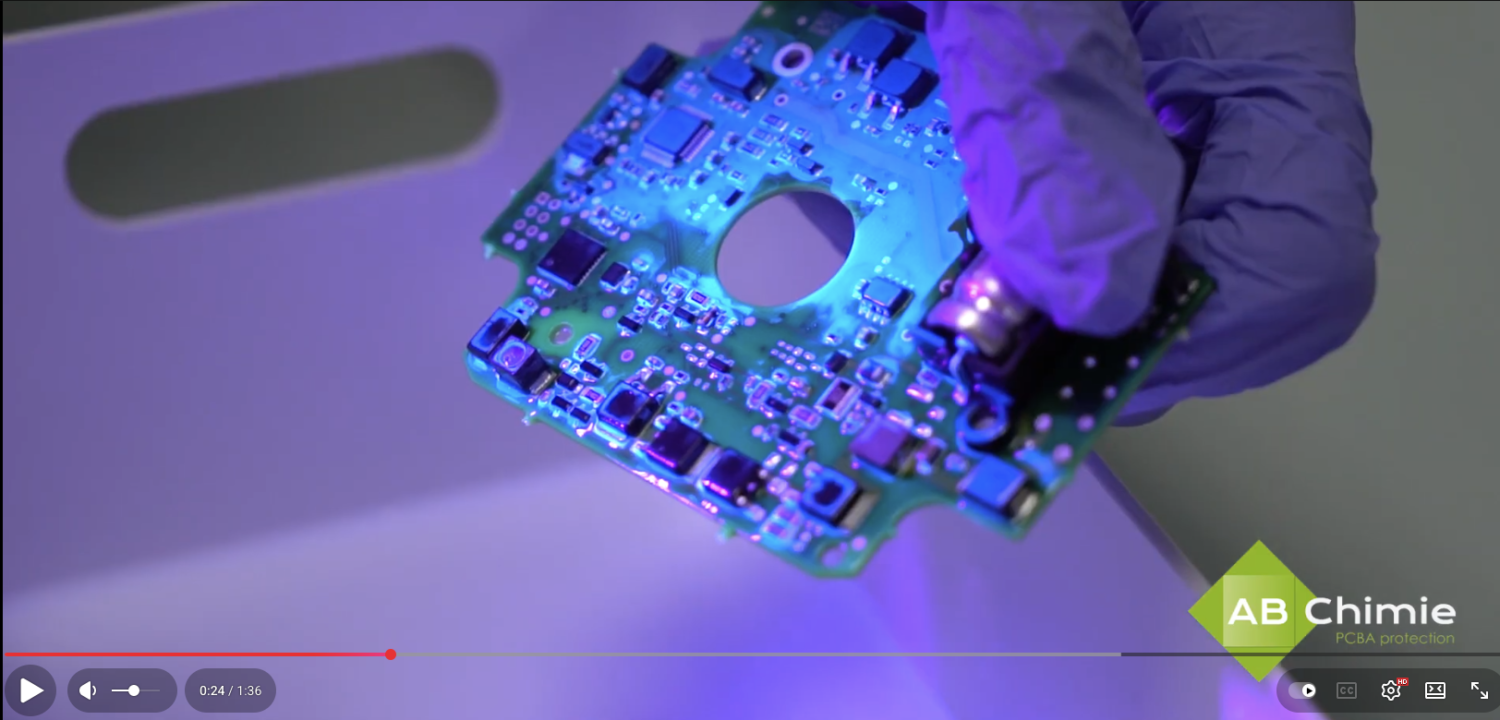

Why Clean PCBA?

Cleaning printed circuit board assemblies (PCBAs) is essential to ensure the long-term reliability of electronic products. Residual ionic contaminants can lead to corrosion or electrical leakage, compromising the performance of the assembly. Removing these contaminants also eliminates solder micro balls, which could cause short circuits or intermittent failures. Proper cleaning improves the adhesion of conformal coatings, ensuring protective layers bond correctly and provide lasting protection. Overall, thorough cleaning directly contributes to the reliability and durability of the assemblies.

Why Clean Screens?

Cleaning stencil screens is equally critical in solder paste printing processes. A clean screen ensures the reliability and consistency of solder paste deposits, maintaining the accuracy of component placement during assembly. It also prevents misprinting caused by clogged apertures or residual paste, reducing defects and rework in production. Regular cleaning of screens is therefore key to achieving high-quality, repeatable soldering results.

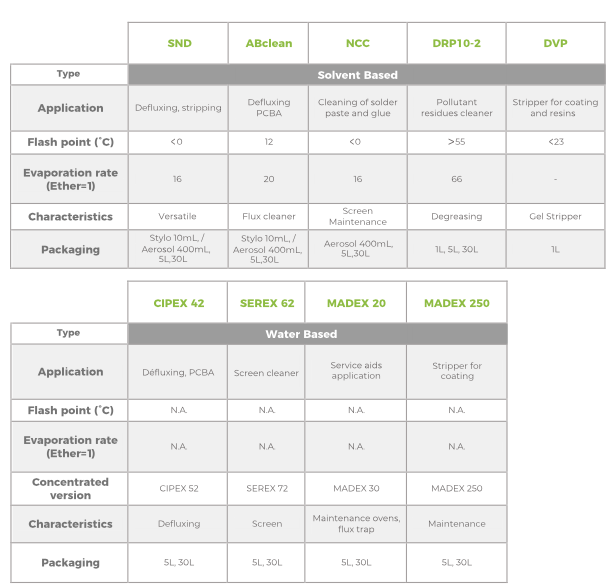

AQUEOUS VS. SOLVENT-BASED CLEANING: WHICH IS RIGHT FOR YOU?

Choosing between aqueous-based and solvent-based cleaning solutions depends on several critical factors specific to your cleaning needs. Here’s what you should consider when making your decision:

- Cleaning Volume

Aqueous solutions are ideal for high volumes, while solvents work well for specialized, smaller batches. - Environmental Policy

Aqueous solutions are typically more eco-friendly, while solvents require more handling and disposal. - Process Speed

Solvent-based cleaning often delivers faster results, but aqueous solutions can still be efficient with the right setup.

Expert Guidance for Choosing the Perfect Cleaning Solution

At ABchimie, we guide you through these key considerations to help you choose the ideal cleaning solution for your specific needs, ensuring both efficiency and reliability.

Our application engineers are here to assist you in making the best decision for your application. Don’t hesitate to reach out — they’re ready to help you find the perfect solution for your cleaning process.

Contact our technical team today to get started. Contact Us

APPLICATION FIELDS

Our expertise in specialty chemistry enables us to deliver tailored solutions designed to meet the technical, environmental, and regulatory requirements of each industry we serve. Our products are customised for a wide range of application fields, from electronics and automotive to renewable energy and industrial manufacturing ensuring reliable performance and compliance in diverse global markets.

AEROSPACE

MEDICAL

DEFENSE

AUTOMOTIVE

INDUSTRIAL

DOMESTICS

Advanced Cleaning &

Protection Solutions

for Reliable Electronics

- Environmentally friendly solutions to protect your PCBA.